News

Smartroof Solution Meets Energy Efficiency Targets

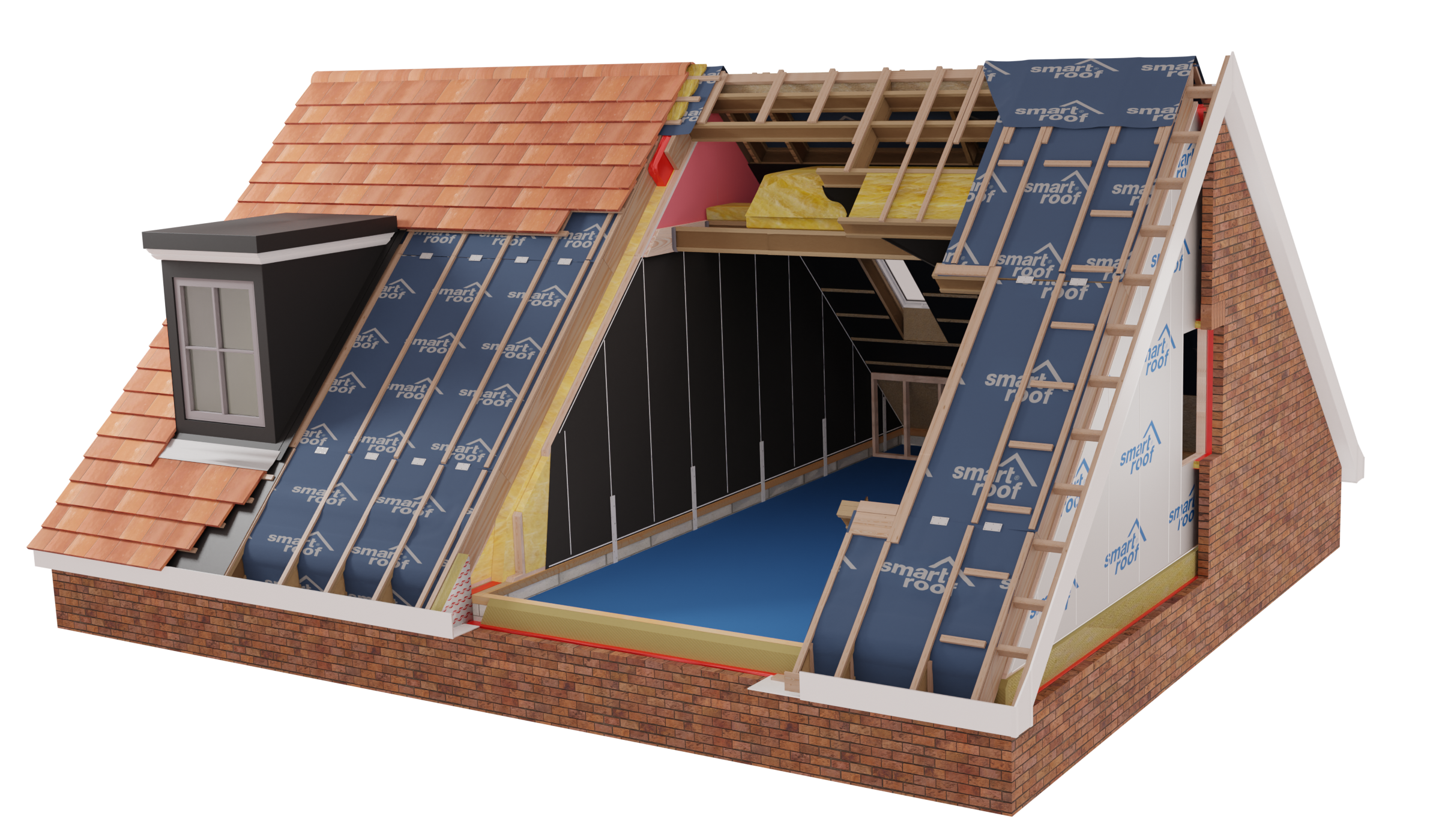

Tom Wright, Design and Technical Director at Smartroof, explains how the company’s offsite manufactured modular roof system is already 2025 compliant, and one of the most cost-effective and efficient ways for housebuilders to address thermal bridging at junction details within the roof build-up.

While the Smartroof system meets the industry’s demand for solutions that enable the construction of better quality homes, it can also help the housebuilder meet the latest energy efficiency targets. It does this in a number of ways including:

- Wide range of U-values

- Junction details

- Vaulted ceiling option

- Dedicated design team

- In-house production facility

Wide range of U-values

The Smartroof solution offers a wide range of U-values. This offers significant increases in design flexibility as its insulation levels can be adjusted to suit the customer’s requirements. Not only does this allow the client to ‘futureproof’ their roof, it can potentially offer significant cost savings as the SAP assessor can trade off gains from one area to another. Achieving higher Fabric Energy Efficiency Standards (FEES) in house types specification’s will be crucial for housebuilders in order to pass SAP and comply with Part L.

Junction details

Smartroof has recently carried out an independent assessment of its junction details to assess the psi value. All details have outperformed the psi values given as default in table K1 for 2020 regs. Smartroof will happily make these details available so that your SAP assessor can take these into account.

The “loft zone” above the ceiling in a room-in-roof system will have a negative effect on SAP calculations and likely result in a higher U-value specification for roof components. The result will be more expensive materials and/or more follow on trades. The majority of Smartroof systems have no structural beams, thus allowing the housebuilder flexibility to adjust their ceiling height. A system with structural beams is likely to be more restrictive when adjusting ceiling height and will result in costly compromises.

Design team

Smartroof’s design department has a wealth of panelised roofing experience. This experience allows the designers to offer various options to its customers when exploring their thermal options. Smartroof has always worked closely with leading SAP assessors and its ‘room in roof’ panel system is already meeting the standards required. Computer modelling enables the company to produce bespoke roofs that are tailored to a client’s needs.

In-house production facility

Production of the Smartroof system in a factory environment ensures no cold spots in the panels or spandrels that may arise from more traditional methods onsite. The system’s design makes it inherently airtight and an ideal roof solution for those developers adopting a fabric first approach. Smartroof’s in-house production facility enables it to stock a wide range of materials and insulations to ensure it meets every customer’s thermal requirements.

Meets requirements

The new SAP 10 methodology is around the corner which means that thermal bridging and junction details will go hand-in-hand. In the past you could apply a set value to it, but now the regulators will want a great deal more information about the actual product and what those values are. With default thermal bridging figures set to increase by about a third, the Smartroof system is ready to meet those requirements and will go some way to helping our homes become more energy efficient and cut carbon emissions.